Achievements

Kenya and Uganda

After thorough market studies on consumer acceptance, in 2013 the Flying Food Partnership introduced crickets in the Nyanza region in Kenya and the Masaka region in Uganda. In an international public private partnership, supported by the Netherlands Enterprise Agency (RVO) we successfully established rearing, processing and retailing of crickets. We trained local trainers in cricket farming. These local trainers guided smallholder farmers in setting up their own small scale insect rearing stations. At the end of the project 120 smallholder farmers, including 80+ women, were actively rearing crickets, with 400 additional farmers prepared to start. Two middle-scale companies had been established with the combined potential to deliver 50 tons of crickets per annum. Three processing companies were drying, grinding and packaging crickets and delivered them to a total of 10 market outlets as snacks or as powder. The crickets will be eaten fried as snack or in samosa, but also dried and grinded into powder to serve as an ingredient for fortified cookies, cricket bread an cricket cookies. At full capacity, the existing supply chain had a potential of delivering 5.000.000 servings per annum. The created value chains were built on a sustainable business model for each stakeholder.

But full capacity has never been met, because in the last year of the project (2018), the cricket populations in both countries were affected by a bacterial infection. This event resulted in a temporary close down of many farmers and a restart of their production was needed with a new healthy parent stock. Trainers and microfinance institutions appeared to be strong and supportive. Last years the amount of cricket farmers is growing slowly and at the moment (2022) around 90 farmers are active. Since 2018, no more infections have occurred.

MIXA in Kisumu

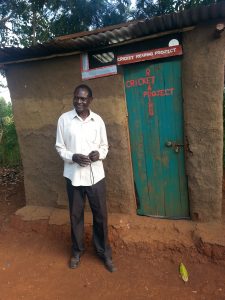

In Kisumu, Kenya the company MIXA Food and Beverages is a stable, successful cricket entrepreneur who rears, processes and sells crickets, but also trains and sells eggs to smallholder farmers. They sell crickets mainly in bread and cookies. They also developed portable pens to rear the crickets in – instead of the plastic crates.

Next steps Kenya and Uganda

The value chain in Kenya and Uganda is still fragile, and need extra support to accelerate the cricket business. In order to have more entrepreneurial power and stable, high quality supply of crickets we do not just work with smallholder farmers, but start with medium sized farms. This entrepreneur will build a farm of 70 m2 containing 500 crates, delivering 63 million eggs and 3,400 kg of fresh crickets annually. This medium farm will also do some basic processing and has links with retail and food processors. This emphasis on a more demand-driven approach, will contribute to more sustainable linkages between producers and the consumer market. This medium cricket farm can handle an out grower model and deliver eggs to 50-100 small holder farmers. We intend to build star-cases with this new approach.

InsectiPro Ltd from Nairobi is active in farming Black Soldier Flies for chicken and fish feed. In 2019 they started with farming crickets and bought the equipment of EntoAfrica, partner of Flying Food. Nina de Groot did an internship at Flying Food during her graduation at HAS Den Bosch and took her knowledge and experience to InsectiPro. She started as product manager and launched in 2022 the Chirrups – a Crunch with a Punch! Chirrups are fried crickets as snack in small sachets. You can buy them in three flavors: Plain, Salt & Vinegar and Barbeque.

Springboard, Nigeria

In Nigeria we kicked off the cricket business, together with Springboard Cooperative and USAID. We trained 43 farmers selected from 10 Springboard communities in Akure, Ondo State, Nigeria. Currently two demo farms are set up and 25 farmers have set-up their own farms. The crickets are growing well, because in this region the temperature is around constantly 30 degrees during day and night. The crickets serve as another source of income for all benefitting farmers. Springboard purchases all produced crickets from farmers to processes bread and muffins fortified with cricket powder.

Rwanda, Burundi and Malawi

Also Malawi, Burundi and Rwanda showed interest to kick off with the crickets-for-food business. We did a market research in those countries and the potential is there. We are looking for entrepreneurs and investors who are willing to jump in the cricket business.